The LevelControl measures the cylinder level via ultrasound. For this, it is necessary that the coupling pad of the device has clean contact with the bottom of the gas cylinder.

Suitable are upright (propane / butane – LPG) steel or aluminium gas cylinders with a diameter of 200 to 350 mm.

Depending on the cylinder type and age, there may be different obstacles to clean measurement.

Here are some examples of obstacles and the corresponding solutions:

Bottle heavily rusted/dirty

Due to the uneven surfaces caused by rust, the ultrasonic signal can no longer penetrate cleanly into the bottle. A measurement is therefore not possible.

In this case, it is recommended to mount the LevelControl in such a way that the coupling pad rests on a surface that is as smooth as possible. In severe cases, the only solution is to replace the bottle.

Bottle stand base too narrow

On such a bottle, the LevelControl has no place underneath. The bottle rests with its entire weight on the LevelControl and squeezes the coupling cushion. This also means that no measurement is possible.

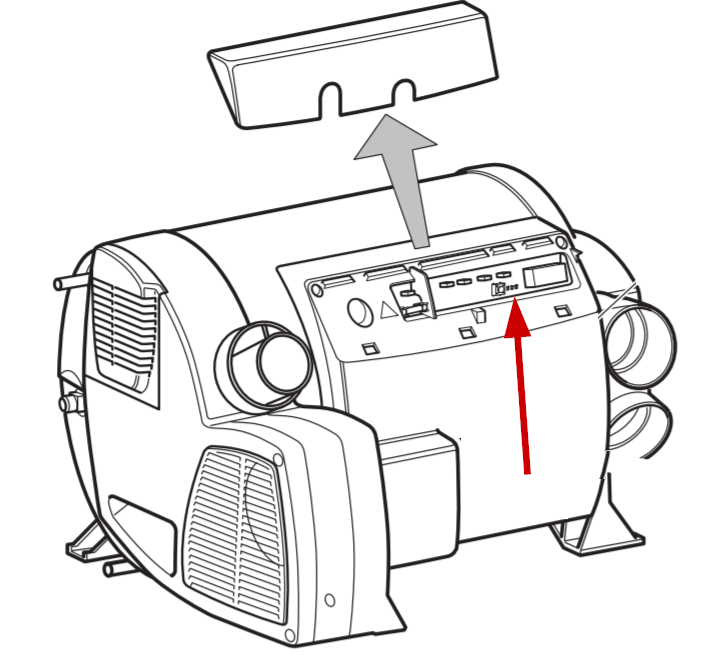

The supplied feet or other distance blocks can provide a remedy.

Bottle base dented/flattened on the underside

If the LevelControl is attached to the centre of such bottles, the coupling pad no longer rests on the ground as desired. A measurement is therefore not possible at this point.

In this case, simply move the LevelControl a little out of the centre.

Tank bottles/gas tanks

Tank bottles have a special interior that enables refuelling (fuel indicator, etc.). This interior deflects the ultrasonic signal of the LevelControl so that no measurement result can be calculated and displayed.

The LevelControl cannot be used on such bottles/tanks.

Thanks to the customers who sent us the photos for better clarification.