For those campers who do not travel during the winter, it is time to put the caravan into its winter quarters and make it winter proof.

For those campers who do not travel during the winter, it is time to put the caravan into its winter quarters and make it winter proof.

You should remember that both the vehicle and also the installed equipment need to be prepared for the shutdown phase.

Some useful care tips from Truma:

On-board battery

The statistical average battery life is anywhere between 3 and 5 years. However we know of cases where batteries have worked for many more years. Of course, this depends on the type of battery and how it is used. To ensure that the battery does not suffer during the winter, it should be removed from the vehicle before the winter and fully charged.

Five important tips about extending the battery life from Truma

1) For longer periods when the battery is not in use it should be disconnected and recharged every 6 to 8 weeks, at the latest every 12 weeks. Please note that the battery is only fully charged after 24 hours.

2) Adapt the charging voltage to the battery temperature. Depending on type, batteries will heat up more or less during the charging process. The direct ambient temperature also has a significant impact on the performance. If a battery temperature sensor is attached, it will record the operating temperature of the battery and will communicate this to the connected charger. The charger then changes the charging curve based on the sensor measurements. This means, the higher the operating temperature, the lower the output voltage; and the lower the operating temperature, the higher the output voltage

3) Note: The operating temperature range of our charging systems is 0°C to + 50°C. If 50°C is exceeded, the charging process is interrupted.

Using a battery temperature sensor is not only beneficial for the battery, it also increases its service life.

4) For periods longer than 24 hours when the battery is not in use, interrupt the power supply (e.g. with cut-out or disconnection of the battery terminals)

5) The battery should be stored in a cool and dry place protected from frost (e.g. cellar)

Batteries in remote controls or the automatic ignitor of the S-heater

To prevent batteries leaking, they should be removed from the remote control, or automatic ignitor. Store the remote control in a dry place.

Boiler Storage Waterheater

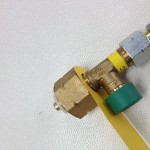

Drain the waterheater via the drain valve.

There are detailed instructions on how to drain the waterheater correctly in this article “Diagnosis – frost damage”.“Diagnose Frostschaden”

Controller System

Always disconnect the pressure controller (or high-pressure hoses) from the gas cylinder to ensure that there is no more gas in the lines.

If there is a gas remote switch, set it to OFF.

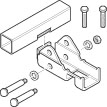

Mover

1) If the Mover is heavily soiled, spray clean with a soft water jet to remove any mud etc.

2) Ensure that there are no stones or branches caught on the Mover.

3) After cleaning, dry and then apply a light coat of spray oil or a similar water-repellent lubricant onto the guide elements of the drive.

Attention: The lubricant may not be allowed to get onto the rollers or tyres!

Engage and disengage the drive units several times to ensure that the lubricant is distributed across all guide elements. Do not park the caravan with engaged drive rollers.

If cared for correctly, both the vehicle and the Truma products will survive the winter without any problems. And you can start travelling again in the springtime without any worries.